Solid Lubricant Coatings-MoS2 (Alfa Moly Coating)

Full Annealing Service :

- Creating a distinct position for ourselves in the industry, we are involved in offering our supreme-class Molykote Coating.

- We ensure that the services offered by us are timely implemented, highly consistent and reliable.

- All the services presented by us are widely required in varied sectors.

- Adding to this, our workers are highly knowledgeable and can maintain proper communication with the patrons.

MOLYKOTE (Molybdenum Disulfide Coatings - MoS2 Coatings) :

- Molykote is a dry film lubricant, commonly used in applications where load bearing capacity, operating temperature and coefficient of friction are primary concerns.

- This coating provides effective lubrication in a wide range of loads, in many cases exceeding 250,000 psi.

- Moly coatings lubricate sacrificially by transferring lubricant between the two mating surfaces, which helps to reduce wear and coefficient of friction.

- Alfamoly is a specially bonded organic lubricant coating which contains solid lubricants like molybdenum di sulphide etc. Like Molykote, Alfamoly has the properties of anticorrosive and solid lubricity.

Xylan Coatings Service :

- Xylan coating is the largest, most complete line of fluoropolymer coatings in the worlds.

- Xylan coatings in which we also cover, TEFLON, PTFE coating have a broad range of properties, which make them ideal for an infinite variety of applications.

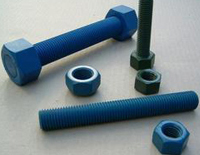

- Xylan/PTFE coating on Bolts, Studs & Nuts is an ideal protestion in corrosive environments, salt water condition & specially for splash zone.

- Xylan coatings differ from traditional fluoropolymer coatings in one very important aspect : they are composite materials. Lubricants with the lowest-known coefficient of friction are combined with the newest high-temperature-resistant organic polymers.

- Together, they from “Plastic alloys” with unique properties:Xylan Coatings are a family of fluoropolymer coatings designed for use on various types of OEM components and fasteners, including Xylan coated bolts to prevent corrosion.

- Xylan is known a heteropolymeric substrate consisting of a repeating β-1,4-linked xylose backbone branched with acetyl, arabinofuranosyl, and 4-O-methyl glucuronyl groups (Figure).

- In addition, xylan may be cross linked to lignin by aromatic esters. In order to efficiently depolymerize xylan to the component monosaccharides, a mixture of different enzymatic functionalities are required, including endo-1, 4-β-xylanases.

Properties of Xylan Coating :

- Tensile Strength (ASTM D1708) : 4000 - 5000 psi

- Elongation (ASTM D1457) : 50.00%

- Impact Strength (ASTM D256) : 13 ft - lb/in

- Hardness (ASTM D2240) : 60 - 90 HB (shore D)

- Abrasion Resistance (Tabor) : > 15 mg

- Coefficient of Friction (ASTM D1894) : .15 - .35 static

- Dielectric Strength (ASTM D149) : 1400 volts per mil

- Use Temperature : -100°F to 500°xF max

- Melting Point : n/a

If you have any query related our products ... We are available